Laminate flooring installed in an apartment or office space is considered a comfortable, durable and practical floor covering. If you follow all the rules and installation features, laying laminate flooring yourself will be simple and affordable, allowing you to get a beautiful and stylish floor.

In order for the created coating to fit perfectly on the floor and serve for a long time, it is necessary to properly prepare the base. An insufficiently dried screed layer or an uneven concrete floor will be the first reason why the created coating will quickly lose its original appearance.

General flooring installation scheme

General flooring installation scheme Moisture from the screed will lead to deformation of even the highest quality and most expensive finishing coating. The rough base must also be perfectly level. To do this, experts recommend laying linoleum, fiberboard or chipboard sheets, or a plank floor on it.

Laying laminate flooring on a wooden floor is carried out without using a sublayer under the laminate. Most often, apartment residents use a special leveling compound.

The technology for laying laminate flooring is somewhat reminiscent of assembling a construction set, so it will take a small amount of time. The exception is laying laminate diagonally, which has some technological features. Each subsequent element is attached to the previous one if it is not fixed at the level of the floor base.

Example of a straight laying scheme

Example of a straight laying scheme The substrate under the laminate is a mandatory layer of the structure. The sublayer under the laminate made of polypropylene foam or polystyrene foam has not only sound and heat insulation properties, but also performs the function of additional leveling of the rough base.

Laying laminate flooring on a wooden floor is carried out without the use of a backing.

But such a lining under the laminate can only mask irregularities up to 5 mm in size. If linoleum is used as a sublayer, then it is advisable to level the base. Linoleum will not be able to smooth out defects or differences in the level of the base.

The technology for laying laminate flooring should assume the presence of a technological gap to the walls. Its size is 10 mm. Why is this gap needed? The formed floor must be able to “move”.

Technology for laying laminate flooring on a concrete floor

Technology for laying laminate flooring on a concrete floor When heated and cooled, any material changes shape (expands or contracts). To prevent laminated panels from deforming when the heating system is turned on, you need to give them the opportunity to expand. Therefore, the technological gap is a mandatory requirement, which includes step-by-step instructions.

Required tools and materials

The technology for laying laminate flooring is quite simple. A substrate for the laminate is installed on the rough base, on top of which the laminated panels are laid. You should also carefully prepare the material for a concrete or wooden floor. Often the finishing coating is mounted on linoleum.

Internal and external structure of laminate boards

Internal and external structure of laminate boards Before you begin, it is important to prepare all the necessary materials that you may need at each stage. The list compiled by professional builders is as follows:

- primer mixture;

- polyethylene film;

- foamed polyethylene layer;

- laminated panels;

- wedges for making gaps for technological purposes;

- special glue;

- plinth and functional fastenings for it.

Step-by-step instructions for installing the material on a concrete or wooden floor involve the use of the following tools and devices:

Laying methods, depending on the selected material

Laminate can have absolutely any color and textured pattern.

Laminate can have absolutely any color and textured pattern. The technological instructions for laying laminated panels on a concrete or wooden floor consists of several sequential processes. Its features depend on what type of material you choose. If the substrate has already been laid, then markings should be made and the panels cut.

The direct installation method is one in which the decorative panels are laid out and connected parallel to the walls. Installation will save money, since pruning costs will be no more than 6-7%.

The herringbone design will make the flooring more aesthetically pleasing and stylish. But it will require the purchase of special laminated panels. Only a professional builder can lay out the panels in a herringbone pattern, since installation is considered the most complex and time-consuming.

How to lay laminate flooring with Click or Lock type locks on a concrete frame or linoleum? Below you will find detailed instructions.

Working with Click-type locks

Working with Click type locks involves the following steps:

Laminate can even imitate tiles

Laminate can even imitate tiles - The installation of elements with such locks begins with the installation of a sublayer under the laminate on the concrete floor. If there is already linoleum on the floor, then this operation can be skipped. Work begins from any side wall, the initial row of laminated elements is laid. Wedges are placed between the wall and the panel, which will subsequently provide a technological gap of 1-1.2 cm. The panels in the first row must necessarily face the side wall with a special protrusion;

- While working, make sure that all locks are in close contact with each other. There should be no gaps or cracks left. In order for the locking connection to close tightly, you need to install the next panel in the previous groove at an angle of 45 degrees, and only then secure it with pressure until it clicks;

- All subsequent laminated panels should be spaced apart. The joints should not be cross-shaped or coincide with each other. The so-called laying of the laminate diagonally is carried out;

- The installation of the second row of elements is carried out as follows: first, the panels are connected in the end lock (a strip of the required size is formed), then this strip is moved and placed in the groove at the same 45 degree angle and pressed until it clicks. The sublayer under the laminate should not interfere with work;

- As construction practice shows, the last row of panels will need to be “adjusted” to the dimensions of the room. Now you will need a jigsaw to cut off the excess part. Don't forget to leave a technological gap.

During the work, it is imperative to ensure that the locks fit together as tightly as possible.

Working with Lock type locks

This installation of laminate flooring on a wooden floor or concrete frame differs slightly from the previous option. The lining under the laminate can also be linoleum, fiberboard and chipboard sheets, polystyrene foam (polypropylene foam). Immediately before joining, the panels are installed horizontally. The tenon of one panel must match the groove of the other. The elements are adjusted using a hammer and a wooden stand. The first row does not have to be laid all the way to the end to begin installing the next one.

The initial laminated element is inserted into the groove of the previous row, then 10 mm are retreated from the end of the first one and connected to the previous row. Then the second panel is adjusted until it is completely connected to the end of the first. The finishing row is adjusted using a mounting crowbar.

Installation with adhesive joint

Technological installation of the coating on a concrete floor or linoleum can also be carried out using special glue. This is how laminate flooring is most often laid diagonally.

There is even a laminate that imitates artistic parquet

There is even a laminate that imitates artistic parquet This technology will require a minimum amount of time and auxiliary tools from you. The use of an adhesive composition can significantly increase the service life of laminated materials. This effect is achieved due to the complete sealing of the joints.

If you fix the coating with glue, you will not have the opportunity to replace the damaged panel. To complete the work, you need to purchase only waterproof glue.

The procedure for laying a laminated coating on linoleum or a substrate is very similar to working with Lock type locks. Only before the final joining of the elements should their ends be coated with adhesive. The amount and consumption of glue is determined during the installation process. If excess mixture appears on the surface, it must be removed immediately with a cloth.

Video

You can watch a video that explains in detail how to properly install laminate flooring.

Beautiful and high-quality flooring is the key to positive emotions. In this article, we will take a detailed look at how to lay laminate flooring with your own hands, from preparatory work and tips for choosing tools, to tips for “bypassing” obstacles during installation.

We save on the work of a master!

Laminate - although a noble coating, its installation can be done with your own hands without much difficulty. In this article we will tell you in detail what's what.

If the floor surface is uneven, then the laminate laid on it will be subject to unwanted deflections. This can lead to failure of the coating, which will be especially noticeable on joint surfaces. Therefore, before laying, the surface to be coated is inspected to identify its unevenness. For these purposes, use a regular level. If there are significant differences in floor height, it must be leveled. In addition, wooden floors are carefully examined to identify boards that have become unusable. Rotten elements are removed and new ones are installed in their place. A wooden floor can be leveled by placing wooden blocks under the boards, which adjust the position of the boards. At the same time, the thickness of the flooring does not increase, which is especially critical for rooms with low ceilings. If it is not possible to adjust the position of the boards, then you can build another layer of plywood or OSB sheets directly over the existing one. At the same time, it must be carefully leveled using the same linings.

In addition to boards, you can use sheet plywood or special wood-fiber floor boards on the floor. These materials also need to be leveled.

Is the floor level?

Leveling the floor with plywood or OSB boards is a mandatory step. Laminate is a rather fragile coating, demanding on the base.

In some types of residential buildings, wooden floors have ventilation holes to protect them from the harmful effects of various organisms and dampness. When laying an additional leveling layer on such a surface, care must be taken to ensure that these holes remain open. After laying the leveling layer, it is necessary to treat it with an antiseptic. The concrete surface is leveled using a screed. Before pouring it, level beacons are installed. Their height is calculated based on the minimum height from the floor to the ceiling of the room. The more beacons are installed, the smoother the surface will be after pouring. To reduce thermal conductivity, you can cover the concrete floor with plywood, having previously laid a layer of waterproofing underneath it.

If the concrete pier has only small irregularities, then it will be sufficient to make a so-called “self-leveling” screed.

Materials and tools used

In addition to the laminated board itself, for carrying out work you will need the following materials:

- Foamed polyethylene backing;

- Waterproofing film for concrete pavement;

- Wedges to ensure clearances;

- Construction pencil;

- Skirting board and fastenings for it;

- Glue;

- Masking tape.

The following tools will be needed:

- Wood saw or electric jigsaw;

- Measuring devices (tape measure, square);

- Mallet;

- Hammer.

The list of everything you need is not that long; all the tools are ordinary and will probably be available to the home craftsman. Instead of wedges, you can use wooden blocks or scraps of the same laminated board if you do not want to purchase special devices.

Selection of material and technology

Before starting work, you should calculate the number of boards needed. The calculation is based on the area of the room. Wherein you need to take a reserve of about 10% for unforeseen expenses, especially if laminate coating is being done for the first time. If the floor is installed diagonally, the number of lamellas increases by another 20%. The underlay placed under the board provides the necessary sound insulation. In addition, for concrete coatings, you should purchase a substrate with increased thermal insulation properties, and also provide a layer of waterproofing. It can be made from ordinary polyethylene film, overlapping it by at least 20 centimeters.

Before laying the substrate, it is necessary to carefully prepare the floor surface, clearing it of dirt and dust. The substrate is not laid over the entire surface at once, but over the area on which the board is directly laid, thus protecting it from excessive contamination. When laying, it is necessary to apply a backing to the walls to a height of approximately 2 - 3 cm. Individual strips of material are butted together and secured with tape.

Before laying the substrate, it is necessary to carefully prepare the floor surface, clearing it of dirt and dust. The substrate is not laid over the entire surface at once, but over the area on which the board is directly laid, thus protecting it from excessive contamination. When laying, it is necessary to apply a backing to the walls to a height of approximately 2 - 3 cm. Individual strips of material are butted together and secured with tape.

DIY laminate installation

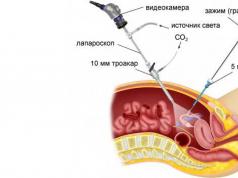

The figure shows how to properly connect laminate panels

The figure shows how to properly connect laminate panels Thanks to our step-by-step instructions, you can install the coating yourself without any problems. There are two main types of laminate locks - " Lock" And " Click" The first type has a tenon on one board and a groove on the other, which are joined together by driving with a mallet or hammer. The second type is easier to install, since the boards are connected by inserting a hook on one side of the panel into a groove on the other at an angle and lowering the inserted board to a horizontal position with a characteristic sound, from which the name of the type of connection comes. " Click» refers to modern laminate assembly technology.

Regardless of the type of lock, installation of a laminate floor begins with the first row. It starts from the window. Wedges are installed near the walls to provide the required clearance. Before laying the row its length is measured to calculate the size of the last board. If it is less than 5 cm, then the first board is cut so that its length and the length of the last approximately coincide. Then they lay out a row, connecting the ends of adjacent boards depending on the type of connection - driving them in with a mallet or a hammer with a block, or snapping them into place.

Regardless of the type of lock, installation of a laminate floor begins with the first row. It starts from the window. Wedges are installed near the walls to provide the required clearance. Before laying the row its length is measured to calculate the size of the last board. If it is less than 5 cm, then the first board is cut so that its length and the length of the last approximately coincide. Then they lay out a row, connecting the ends of adjacent boards depending on the type of connection - driving them in with a mallet or a hammer with a block, or snapping them into place.

The second row is marked so that the ends of the boards do not coincide with the ends of the boards of the first row. For example, if the first row started with a whole board, then the second row starts with a trimmed one no less than 30 - 40 centimeters. Thus, a staggered order of lamellas is obtained, ensuring uniform load on the panels. Laminate cutting is done using a hacksaw or jigsaw, which significantly speeds up the process.

The second row is marked so that the ends of the boards do not coincide with the ends of the boards of the first row. For example, if the first row started with a whole board, then the second row starts with a trimmed one no less than 30 - 40 centimeters. Thus, a staggered order of lamellas is obtained, ensuring uniform load on the panels. Laminate cutting is done using a hacksaw or jigsaw, which significantly speeds up the process.

Connecting rows when using " Click"- the lock can be made in two ways. You can first completely lay out the second row without connecting it to the first. Then lift it a little and insert the hooks into the grooves and snap the entire row into place. You can also insert the first board of the second row into the lock with the boards of the first, and insert subsequent panels at some distance from the end of each other, then driving them into the lock using a mallet. In the same way we connect “ Lock" - locks. We connect the last panel of the row to the penultimate one using a clamp, having previously measured its length taking into account the gap to the wall.

Connecting rows when using " Click"- the lock can be made in two ways. You can first completely lay out the second row without connecting it to the first. Then lift it a little and insert the hooks into the grooves and snap the entire row into place. You can also insert the first board of the second row into the lock with the boards of the first, and insert subsequent panels at some distance from the end of each other, then driving them into the lock using a mallet. In the same way we connect “ Lock" - locks. We connect the last panel of the row to the penultimate one using a clamp, having previously measured its length taking into account the gap to the wall.

The last row of covering may require trimming along the long side. If the lock is being installed " Cry"In the first way, then no additional tricks are needed. When assembling the Lock locks using the second method, you will have to use the clamp again, as when laying the last lamellas of the row. The installation of adhesive laminate stands apart. Its main advantage is its use in rooms with increased complexity (for example, in the kitchen) and increased reliability and longer service life compared to conventional laminated floors. The installation of such a floor is based on the same principles and methods as the assembly of laminate flooring into a “Lock” lock, only the additionally connected surfaces are covered with a special glue. The laminate is assembled in stages - every 3 rows there is a break to dry the glue. It is recommended to use such floors after complete drying, after about 10 hours. The disadvantage of such a coating is the impossibility of subsequent disassembly without destroying the structural elements.

The last row of covering may require trimming along the long side. If the lock is being installed " Cry"In the first way, then no additional tricks are needed. When assembling the Lock locks using the second method, you will have to use the clamp again, as when laying the last lamellas of the row. The installation of adhesive laminate stands apart. Its main advantage is its use in rooms with increased complexity (for example, in the kitchen) and increased reliability and longer service life compared to conventional laminated floors. The installation of such a floor is based on the same principles and methods as the assembly of laminate flooring into a “Lock” lock, only the additionally connected surfaces are covered with a special glue. The laminate is assembled in stages - every 3 rows there is a break to dry the glue. It is recommended to use such floors after complete drying, after about 10 hours. The disadvantage of such a coating is the impossibility of subsequent disassembly without destroying the structural elements.

Avoiding obstacles during installation

The main obstacles when laying laminate flooring are heating pipes and various wall protrusions and depressions. The geometric delights of the walls are avoided by cutting the boards, taking into account the necessary technological gaps.

When bypassing heating pipes, you have to use additional tools.

First, find the position of the passage of the pipe on the board. Then, using a special drill, for example, a feather or Forstner, a hole is made in the board, which should be slightly larger in diameter than the pipe. After this, the board is cut in the transverse direction in the center of the hole into two halves. One half is installed from the wall to the pipe, and the second to the rest of the row.

Laying diagonally

This option for installing a laminated floor visually expands the area of the room. Its only significant drawback is the increased consumption of material. Laying is done from the corner near the window. The first board of the first row is cut from the end at the wall at an angle of 45 degrees. Next, the entire row is laid out, running diagonally across the room. Then two rows are docked to it on each side. The initial and final boards are cut along the wall with the geometry required for installation and with the calculation of gaps.

To simplify the task, first stretch a diagonal of fishing line, which serves as a guide. You can lay out whole boards first, and only then start trimming around the wall panels. This way things will go much faster.

After installation is completed, all wedges are dismantled. The protruding edges of the substrate are cut off, leaving the required overlap on the wall. A plinth is installed around the perimeter of the room. Its elements are attached to the walls, and in no case to the laminate. Doorways are equipped with thresholds, for example, made of metal. To make the laminate last longer, should be protected from water. This floor is washed with a damp cloth, after which it is advisable to wipe its surface dry. To protect the material from the harmful effects of water, you can treat the joints with a sealant when laying. If there is heavy furniture installed in a room with laminated flooring, then care must be taken to ensure that the outer layer of the floor is not destroyed when moving it. You should also avoid contact of the laminate with sharp, heavy objects. Damaged boards lose their aesthetic appeal and their technological properties.

It is not recommended to install laminated boards on a warm electric floor. The maximum temperature of the bottom surface of the laminate is 27 degrees Celsius. If it is exceeded, the panels will begin to dry out and the floor will deform. Installation work on laminate flooring equipment is carried out in rooms with a temperature not higher than 30 and not lower than 15 degrees. Relative humidity should be between 40 - 70%. When calculating thermal gaps, it is necessary to proceed from the following calculation formula: for each meter of coating length, the technological distance to the wall is 1.5 mm.

It is not recommended to install laminated boards on a warm electric floor. The maximum temperature of the bottom surface of the laminate is 27 degrees Celsius. If it is exceeded, the panels will begin to dry out and the floor will deform. Installation work on laminate flooring equipment is carried out in rooms with a temperature not higher than 30 and not lower than 15 degrees. Relative humidity should be between 40 - 70%. When calculating thermal gaps, it is necessary to proceed from the following calculation formula: for each meter of coating length, the technological distance to the wall is 1.5 mm.

If you are unsure of covering a laminate floor with your own hands, you can entrust this work to professionals. The cost of specialist services is approximately 200 - 250 rubles per square meter.

One of the most inexpensive, beautiful and practical materials used for flooring is laminate. It can imitate almost any surface, has a long service life and does not require special care. But the main thing is the ease of installation. Modern laminated boards have a simple and convenient fastening system. Everyone can lay laminate flooring with their own hands. Step-by-step instructions will help you do everything exactly the first time.

Floor surface requirements

Laminate is a multilayer material, its lower part is made of special paper that protects the inner layers from moisture. The main part of the laminate (bearing board) is compressed high-density wood chips (HDF or fiberboard). The strength of the entire coating depends on its thickness. The locking elements are located on the side parts of the load-bearing plate. The fiberboard panel is covered with a film to increase moisture resistance. A layer of decorative paper is placed on top of the film, on which a pattern imitating wood, tile, stone or other surface is depicted. The topmost layer of the board is acrylic resin or melamine coating, which protects the drawing from abrasion, fading, and water ingress. A texture is applied to the top layer so that the coating resembles wood or stone to the touch.

Thanks to convenient locking joints, laminated boards are easily and firmly fastened together. Assembling the flooring is reminiscent of assembling a construction set. Before laying laminate flooring, it is necessary to carefully prepare the floor surface of the room in which it will be installed.

If the floor topography is uneven, the locking fasteners between the laminated boards will become loose and may eventually break. This will lead to the appearance of creaks, cracks between the boards with a gradual increase in their size, and dust and dirt getting into the cracks. The floor requirement for laying laminate is a flat surface with a height deviation of maximum 2 mm on an area of 2 sq. m. Only on a well-leveled surface can the flooring last more than 10 years.

What kind of coating can be under the laminate?

Before considering the question of how to lay laminate flooring, it is necessary to determine on what floor the laminate can be installed.

The slats are laid on old tiles or linoleum, concrete or wood floors. The main thing is that the surface is smooth:

- It is best to lay laminate flooring on a flat concrete base. It can be leveled using a self-leveling floor.

- Installing laminate flooring on a wooden surface is a high risk. It is not recommended to do this if the old boards have dried out, started creaking and become different in height. The problem with squeaks on individual boards can be solved by nailing them. If this does not help, then the floor should be re-laid. To level a wooden floor, moisture-resistant plywood is placed on top of it (recommended thickness is 10-15 mm) and fixed with self-tapping screws or nails.

- Laying laminate over linoleum provides additional sound insulation. This option is not suitable if the linoleum is old, swells and collapses; it can ruin the appearance of the new coating. It is recommended to remove the linoleum if it is too soft: the laminate above it will begin to creak.

- Laying laminate over tiles only makes sense if the tiles are intact and level.

- You cannot install laminate flooring over fragile coverings, such as old carpet.

The surface on which the laminate is to be laid must first be thoroughly washed and dried.

Preparation of tools and calculation of materials

Laying the laminate is carried out using the following tools:

- roulette;

- pencil (marker);

- construction square;

- hammer;

- stationery knife;

- jigsaw (wood saw or miter saw);

- set of wedges 15 mm thick;

- adhesive tape for backing;

- wooden block.

Advice! Before installation, you need to calculate the amount of consumables. With traditional installation (with boards placed along the length or width of the room), the required material is calculated according to the following scheme: the area of the room is calculated (the length is multiplied by the width) and another 10% is added. An additional part of the materials (10%) is purchased taking into account the costs of cutting the boards.

When laying the flooring diagonally, 20% is added to the room area. In this case, the boards do not lie straight, but at an angle of approximately 45 degrees. This makes the room visually appear more spacious.

Before installing the floor covering, we lay a polypropylene underlay (2 mm thick). This is enough if there is linoleum or a wooden floor (old parquet) under the laminate. If the base of the floor is concrete, then first you will need to lay a vapor barrier layer - a diffuse membrane or simple polyethylene 3 mm thick. The vapor barrier layer is laid overlapping.

If money allows, you can choose a more expensive balsa wood base. It provides improved sound insulation. The substrate is laid joint-to-joint over the entire area of the room. It is fixed with adhesive tape. There is a laminate on sale that already includes a soundproofing lining. There is no need to place a separate polyethylene backing underneath it.

Important! Before you start laying laminate flooring with your own hands, you need to unpack the material and leave it in the room where it will be installed for 2 days. The laminate must get used to the microclimate of the room. The room temperature should be above 18 degrees, and the air humidity should be at least 70%.

Laying process

Traditionally, installation begins from the light source (window) to the door. This way, the finished floor covering will look like a single solid canvas: the light from the window opening will make the joints between the boards invisible.

The first board is laid out on the laid and fixed substrate. It should be located at a distance of about 15 mm from the wall. This gap is necessary to compensate for changes in the size of the coating as temperature rises or humidity increases. If you lay the boards close to the walls, they may become deformed. The size of the gap is fixed with wooden wedges.

The second board is inserted perpendicularly at a slight angle into the end of the first and lowered to the floor under pressure. The panels must be tightly fastened together. To fit them to each other, place a wooden block at the end of the second board and hit it with a hammer. Under no circumstances should you use a hammer directly on the side of the board: this can damage the lock fastening.

When laying the last lamella of the first row, it will need to be trimmed. The board is turned over with its back side up, placed against the wall and, focusing on the penultimate board, using a corner with a pencil, draw a cut line. The required part is cut off with a jigsaw (hacksaw) and attached to the end of the row.

The next row begins with the remainder of the previous board (provided that this remainder is more than 20 cm in length). With this installation method, the floor covering looks like brick laying. This design is considered the most durable. In addition, there are savings on materials.

After laying the second row, it is fastened to the first: the boards are raised above the floor and inserted at an angle of 30 degrees into the locking grooves of the first row. If everything is done correctly, you will hear a click and the boards will be securely fixed to each other. All other rows of laminated boards are laid in a similar manner. Just don’t forget to leave a distance between the laminate and the walls. After the repair they will not be visible, since all the gaps will be covered with plinth.

If the laminate does not have a locking connection, then specialized glue is used to fasten the boards together. When installing the last row, you will have to cut the boards longitudinally from the wall side. In most apartments, the walls are unlikely to be even, so it is necessary to measure the distance from the wall to the boards both at the beginning and at the end of the row, so that in some places there are no gaps between the covering and the baseboard. Additionally, you can protect the seams between the boards from moisture by using a sealant.

During the installation process, it is necessary to provide for the presence of protrusions, heating pipes, communications and other fixed elements in the room. For them, it is necessary to cut appropriate holes in the laminated boards. When installing laminate around pipes, a cut location is drawn on the back of the board, taking into account the distance from the wall. The cutting line should run through the center of the pipes. Holes are drilled in the board. They should be a couple of centimeters larger than the diameter of the pipes.

The panel is sawed along the marked line, the cut areas are covered with glue, and parts of the panel are glued around the pipes. To hide the cutouts, special decorative linings for pipes are purchased and installed.

If there is a central heating radiator in the room, the board is placed directly under it up to the wall (maintaining the required gap). To do this, you will need to cut off part of the locking connection of the adjacent lamella. In order not to lose the strength of the connection, the joints between these two boards are covered with glue.

Installing thresholds and eliminating joints with other floor coverings

Very often, laminate flooring needs to be somehow combined with the flooring of another room. For this purpose, thresholds are set. The highest quality and most reliable of them are made of metal, the most common are made of wood, they are suitable for any coating. The shape of the thresholds can be straight or curved. The choice depends on the design of the room.

Typically, thresholds are divided into the following groups:

- Single-level. They are used in a doorway when joining laminate flooring located in different rooms.

- Multi-level. They are used when joining laminate flooring with other materials: tiles, linoleum, carpeting.

- One-sided. Used when connecting to a fireplace or entrance door.

- Angular. Used on the edges of laminate flooring, for example on steps.

The joints can be made without thresholds. If the laminate and tile are on the same level and close to each other, then the gap between them is filled with sealant. Such joints are made quickly, but cannot be dismantled.

Installation of skirting boards

When the area of the entire room is covered with laminated boards, you can move on to the final stage - installing skirting boards. First you need to remove all the wedges and trim off the excess backing. The baseboard is not attached to the floor or to the laminate, but only to the wall.

Construction stores have a large selection of skirting boards of different materials and colors. Wooden plinths should only be used in rooms with perfectly smooth walls. Otherwise, it is recommended to choose a plastic baseboard. If wires are laid under the baseboard, they must be secured in special recesses. Cheap models of skirting boards are attached to the wall using self-tapping screws or dowels. More expensive models are equipped with special mounts that are screwed to the wall.

Laminate flooring is attractive due to its speed and ease of installation. Behind these advertising statements, not everyone will see a lot of problems, nuances and features that must be taken into account. Need a reliable source on all the styling tricks? Read our article.

When purchasing laminated parquet, do not be lazy to ask the sellers for booklets on the correct installation of the flooring material. Large factories always provide information support to their points of sale. These are flyers about new products and their features, booklets on the rules for choosing flooring, brochures on installation and maintenance.

First of all, you need to choose the right wear resistance class And thickness coverings. In stores you can find the following types:

- 31 class 6-8 mm thick - for residential premises with light foot traffic (bedrooms, guest rooms);

- class 32 with a cross section of 7-11 mm - for rooms with an average level of traffic (corridors, kitchens, halls, small offices);

- 33 class 8-14 mm – for places with high load levels (offices, shops, kindergartens);

- Class 34 with a thickness of 8-14 mm - commercial, industrial and public structures with intense loads (shopping centers, entertainment complexes, bowling alleys, gyms).

Let us explain with an example why this parameter affects styling. As a budget option, buyers often choose class 31 or 32 flooring with a thickness of 6-7 mm for the entire apartment. Sellers and craftsmen, as a rule, “forget” to mention that slabs of this cross-section require a perfectly flat, almost mirror-smooth floor without the slightest differences or irregularities. Otherwise, the finishing will last no more than 2-3 years. In addition, the thinner the slab, the less weight it will withstand, especially in the most vulnerable part - the lock. That is, for example, in a library with heavy bookcases, a coating of at least class 33 with a lamella thickness of at least 12 mm is required.

After choosing a class and design, consider layout option, especially if you are going to lay the flooring yourself. It happens:

Separately, we note the styling format. The fact is that there are several installation methods long floor coverings:

If you want to lay the laminate yourself, think about how exactly the floor will be formed in different rooms - as a single contour (continuous) or separately. In the first case, the floor seems to “flow” from one room to another. Undoubtedly, it is beautiful, but you need to remember that laminated parquet is a derivative of wood. This means that it has a certain coefficient of seasonal change in linear dimensions. Roughly speaking, if compensation gaps are not provided for a low-density coating, then swelling of the floor at the seams is guaranteed. If the seller cannot provide the necessary data, look at the instructions for the laminate, where the maximum room area for continuous installation will be indicated - from 25 m2 or more.

For large areas, it is advisable to use the second option, in which the floor is divided - expansion gaps are formed. Subsequently, they are covered with a decorative profile (aluminum or plastic thresholds).

To find out exactly how best to lay laminate flooring, try modeling it on paper. The drawing will clearly demonstrate the pros and cons, and will allow you to choose the optimal installation parameters.

Required tools and materials

To work, you will need the laminate itself, a substrate 2-3 mm thick, and a waterproofing film of 150 microns and above. Besides:

- Hygrometer and level;

- Compositions or materials for leveling the base: self-leveling floors, levelers, chipboard, fiberboard, gypsum fiber board, plywood or OSB for forming a dry prefabricated screed.

- Special treatment agents: strengthening primer for cement, gypsum or concrete floors, antiseptic or fire-bioprotective compositions for wooden bases.

- Jigsaw or file with blade for chipboard, wood;

- Spacer wedges or bars for creating expansion gaps around the perimeter of the room;

- Ruler, pencil, adhesive tape;

- Mallet, z-shaped striker;

- Means for treating the tongue-and-groove system (if necessary): impregnations or wax mastics to protect locks from moisture, sealing gels, etc.

If the base is sufficiently prepared, all you need is a tool for cutting lamellas, wedges, a hammer and a ruler with a pencil. The rest will be done by the hands of the master.

Do-it-yourself laminate installation: step-by-step instructions for beginners

Make sure the flooring is the same brand and from the same batch. Every year, each manufacturer releases new collections and updates old ones. The shade, pattern, thickness of the slab, and even the shape of the lock may change. Because of this, assembling a single canvas will be problematic.

Before installation, laminate should be brought into the room and left for 48-72 hours to acclimatize the material. According to the recommendations of the manufacturers, the optimal climatic conditions for installation are:

- Temperature: from +16 to +25 ºС;

- Humidity: 40-70%.

- The heating system “warm floors” was turned off 5-7 days before the start of work.

- Moisture content standards for:

- Interfloor slabs – 4%;

- Screeds of cement-sand, cement-gypsum and gypsum type - 2.5-5%;

- Boards – 12%.

The installation process is carried out in several stages:

Step 1. Preparing the base

The surface must be clean, level, dry and durable. It is advisable to remove old coatings completely, including paint, bitumen and others. After this, you additionally need to check the floor with a level, level and prime if necessary.

Differences should not exceed 2 mm per 2 meters.

Important! Recently, some manufacturers have allowed installation on old linoleum, provided that the flooring material is thin (up to 2 mm thick), lies tightly, and there are no holes, dips or other defects underneath.

Ceramic tiles, porcelain tiles and carpets are not included in the list of acceptable bases for laminate flooring.

The next stage is the laying of waterproofing and damping material. First, spread the film over the base with an overlap of at least 15 cm and secure it with tape.

Important! Waterproofing is only needed for a concrete floor; it cannot be installed on a wooden base.

Next, you need to lay out the sheet or roll backing end-to-end and secure the joints with adhesive or aluminum tape. If you purchased a laminate with a backing layer already glued, then this step is skipped.

Laying and fixing the substrate under the laminate.

Step 2. Assembling the cover

Installation is carried out in the selected direction sequentially from the longest wall. Spacers 8-10 mm wide are placed between the walls and the laminate at intervals of 40-60 cm. The first lamella is applied to the enclosing structure, the next one is inserted into the narrow end at an angle of 30° and snaps into place without moving. So until the end of the row.

The following is assembled from a fragment of a plank no less than 30 cm long. The slats are connected along the long side in accordance with the instructions - either by applying and then pressing, or by corner joining. If you need to bypass pipes, columns or communications, a segment is cut out of the strip taking into account a compensation margin of 8-10 mm. In the future, this area can be covered with special decorative overlays.

Before laying the last row, you need to carefully measure the width and file the slats to the required size on the groove side. After fixing, remove the spacer wedges, install a plinth around the perimeter, and install thresholds in the doorway. In this case, the baseboard is attached to the wall, and not to the floor.

Advice! If you need repairmen, there is a very convenient service for selecting them. Just send in the form below a detailed description of the work that needs to be performed and you will receive proposals with prices from construction teams and companies by email. You can see reviews about each of them and photographs with examples of work. It's FREE and there's no obligation.

It has become a sought-after service in the market. Naturally, not everyone is ready to contact construction teams carrying out installation work. How to do your own styling quickly and without problems - we give simple step-by-step instructions.

Types of laminate installation

There are a number of installation methods. The most common ones are:

- traditional;

- diagonal.

Recently, the herringbone method has appeared, but it is quite complicated and requires special skills and labor-intensive work. Therefore, they usually prefer to assemble laminate flooring using only the two methods mentioned above.

Diagonal laying of laminate allows you to visually make the room larger and more spacious. However, it will require purchasing more boards, since a lot of material will be wasted.

Also read materials:

When installing in the traditional way, the boards are laid parallel to the wall from the window. Laying the laminate in this way allows you to visually hide the joints. Under no circumstances should boards be laid across the window - then the light, falling at an angle to the joints, will highlight them. When laying diagonally, the slats are placed at an angle of 45 degrees with respect to the wall. In this case, the angle of incidence of light from the window does not in any way affect the perception of the floor - the joints of the finishing elements are not noticeable in any lighting.

Types of installation of finishing boards

There are also only two of them:

- adhesive connection;

- lock connection.

Advantages of a locking connection– ease of assembly, speed of operation. In this case, laminate boards have special grooves and tenons that are inserted into each other, forming a kind of lock.

Advantages of adhesive joints in that it makes the floors more resistant to moisture, since the risk of water getting into the grooves and gaps that still form when laying the laminate is eliminated. Installation becomes more labor-intensive. But this is justified in a number of rooms - especially in the kitchen, where the likelihood of water spillage is high.

Review of laminate locks (video)

Material calculation

Laying the substrate

The underlay is laid on the prepared floor surface. It's not difficult to do it yourself. The main thing is that the size of the substrate must correspond to the size of the floor. Lay the material without overlap, end-to-end. If the substrate is sheet, then it is laid with an offset - just like bricks are laid in the walls. The joints between the edges of the substrate are secured with tape so that it does not move. After this, the actual laying of the laminate begins.

Underlay for laminate (video)

Types of connection

If an adhesive connection is selected, a sealant is applied to the locks before installation. If the laminate has “lock” locks, then each board is attached separately, and the joint is made with the adjacent board and the top row of boards. If the connection is “click”, then first the boards are attached at the ends, and then row to row.

Installation in the traditional way

- This method is the simplest and you can do it yourself without any problems. The instructions for laying laminate flooring state that work should begin from the wall and perpendicular to the window.

- The first row must be assembled close to the wall, taking into account the compensation gap of 15 mm. In order to keep the gap constant, wedges are used. In this case, the board is placed so that the grooves are located towards the wall.

- Next, we lay our laminate in the first row - the second board is attached to the end of the first placed board. Immediately use a level to level the slats so that they are perfectly straight. The boards should run in a straight line, strictly perpendicular to the window to the opposite wall.

- The last board rarely fits perfectly into the size of the wall and will have to be cut. Therefore, first, the distance to the wall from the already installed board is measured along the floor, taking into account the compensation gap. Then the board is marked and cut with a jigsaw.

- The second row is laid in the same way. Starting work can be done with an already cut piece of board to save material. The tenons are inserted into the grooves and snap into place.

- After laying the row, the boards are inserted tightly together - for this you take a wooden hammer and a wooden block. The block is applied to the board and hit with a hammer - then the locking joint will fit tightly and the gaps between the boards will not be visible.

- This is how a row is placed behind a row. The last row may not fit entirely and then you will have to cut the boards lengthwise.

Diagonal laying

- The first board is laid from the far corner of the room. To orient the lamellas and mark them correctly, you will need a carbon ruler with sides of 45 degrees. After cutting the board, wedges measuring 15 mm are placed on the walls and the lamella is placed in the corner. The first row consists of one board.

- The second row already consists of two boards. The main thing is that the end connection of the elements falls on the center of the first board. Having measured the length of the lamellas, cut the corners again at 45 degrees - they will fit against the wall. Connect the rows together. To make the floor look beautiful, it is important that there is a distance of 20-40 cm between the ends of the boards of adjacent rows.

- In this way we lay row by row, not forgetting to knock together the rows of laminate with a wooden hammer in order to make the gaps invisible and get rid of cracks.

.jpg)

Laying laminate flooring is not particularly difficult - you can do it yourself, following the instructions, within one day.

Master class on laying laminate flooring (video)